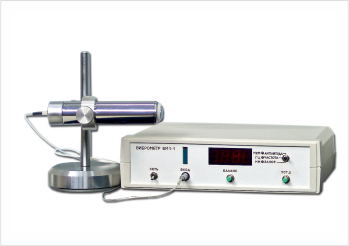

CONTACTLESS VIBROMETER

Designation

The vibrometer is designed for non-contact measurements of the vibration amplitude in metallic surfaces. They can be tools and machinery parts as well as ultrasonic sensors.

The device can be used for non-contact measurements of linear displacements in metal products, for controlling the part sizes, and estimating the part deviations from the specified sizes.

Application

Ultrasonic engineering, machine tool building, mechanical engineering, power engineering.

Modifications to the device for different frequency ranges can be done.

The specifications of a vibrometer used to measure fluctuations in the ultrasonic frequency range are given here as an example.

| Measurable amplitude, max., µm | 200 |

| Measurable vibrations frequency range, kHz | 5…50 |

| Measurement error for vibration amplitude, µm | 2 % + 0,1 |

| Minimal diameter of the surface under test, mm | 6 |

| Operating range of gaps between sensor and target, mm | 0.5 … 2.5 |

|

Dimensions: System, mm Sensor, mm |

235x65x180 d28x135 |

| Weight, kg, no more | 1,5 |

| Measurement modes: |

amplitude measurements; gap measurements |

Within the operating range of gaps between the sensor and the vibrating surface the indications are independent of the size of the gap. The built-in gap indicator ensures precise setting and control of the gap.

Operation conditions

| Temperature, Ń | 15…35 |

| Relative humidity, % | 30…80 |

| Supply voltage V, Hz | 220; 50…60 |

Operation principle

The system operation is based on recording the capacitance variations of the gap between the fixed electrode of the sensor and the surface, the vibration amplitude of which must be measured.

The gap capacitance vibrations are converted into an electric signal. This signal is indicative for evaluation of the mechanical vibration amplitude for the surface under test. The amplitude is calculated automatically by the software tools in real time.

The vibrometer incorporates an automatic compensation mechanism for sensitivity variations caused by the changing gap width. This compensation mechanism ensures the specified measurement accuracy within the operating gap range.

In order to reduce the measurement error resulting from the temperature and time instability of the measurement circuit parameter, there is a balancing option, embedded into the vibrometer. During balancing the parameters of the measurement circuit are automatically fine-tuned to the sensor’s own capacitance.

In the static mode the regular verification of the vibrometer is done by measuring the sensor specified linear displacements in relation to the fixed electrode. In this mode the system can also be used as a non-contact linear displacement measuring unit within the range of 0 …… 1000 µm.

Deliverable package

Vibrometer – 1 piece.

Sensor – 1piece.

Tripod to mount the sensor – 1 piece.

User’s manual – 1 copy.

Delivery terms and conditions

The delivery terms and conditions for the contactless vibrometer are set forth in the Delivery / Development Agreement.

The date when the product is transferred to the Customer or his authorized carrier (in case, the express mail services are used) is considered the delivery date.

The products are delivered in one batch within no more than 20 calendar days from the date the advanced payment arrives to the bank account of the Developer.

Product warrantee liabilities

The guarantee service term is 12 months from the delivery date (as per the waybill).