WE OFFER

The technology and ultrasonic equipment to be used in the liquid-penetrant testing procedures, such as:

- ultrasonic baths, ultrasonic generators, portable and stationary cavitometers.

- consultancy and technical support.

Ultrasound is used during the basic stages of the liquid-penetrant testing:

-when preparing the products for testing;

- when infiltrating defects with the penetrant;

when removing the excessive penetrant, and during the final cleaning of the product.

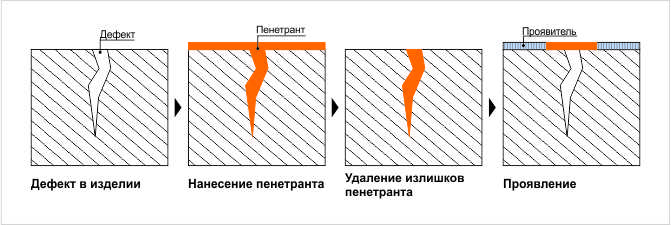

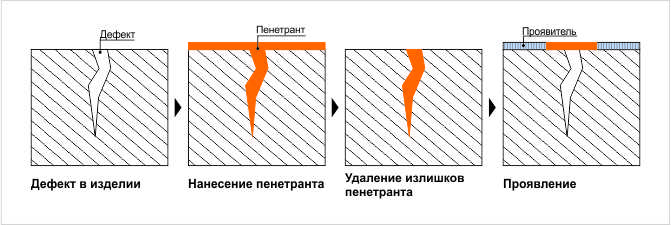

The basic procedures of liquid-penetrant testing

As soon as the product has been prepared for testing, its defects are filled with the penetrant.

While excessive penetrant is removed from the product's surface; the penetrant is preserved in the hollows of the defect itself. Then the surface under test is covered with a developer solvent.

As the penetrant is absorbed by the developer solvent due to the sorption and diffusion effects, a trace of the defect is visible on the surface, brightly colored and luminescent in ultraviolet light. In case a self-developing penetrant is used, there is no need in covering the surface with the developer solvent.

The width of the defect trace greatly exceeds its corresponding size. Due to this it is possible to reveal even minute defects (with openings as little as 0.5 µm and less) in products of any sizes and shapes, made of metals, plastic materials, glass, ceramics, composition materials, etc.

Ultrasound in liquid-penetrant testing

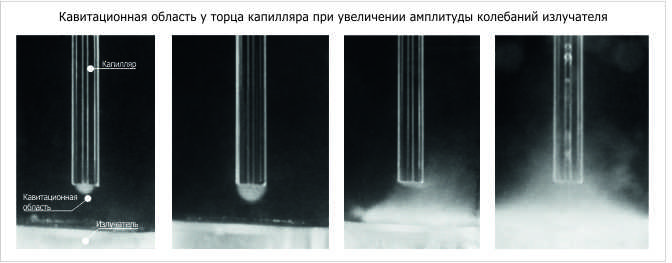

The core of the technology offered is the ultrasonic capillary effect, namely the phenomenon of increased liquid penetration depth and rate (or the rise height) observed in capillary channels, as a result of exposure to ultrasound.

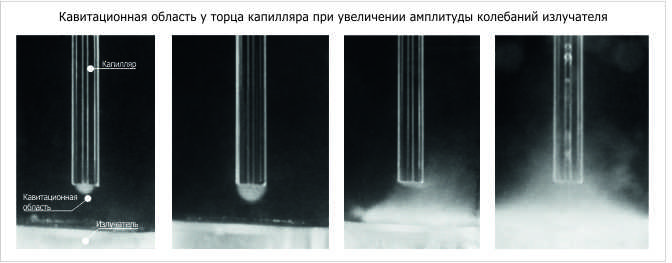

The ultrasonic capillary effect has a cavitation nature. The flow of liquid, directed into a capillary is due to the cavitation hollows (bubbles) asymmetrically collapsing at the entrance of the capillary channel. Formed in this microjets of liquid, entering the capillary, cause a net effect of increasing the rate or the height of the capillary rise (or the penetration depth) of liquid.

The advantages of using ultrasound

The use of ultrasound ensures an increase in the test sensitivity, and the possibility to replace toxic inflammable liquids with harmless fireproof compounds.

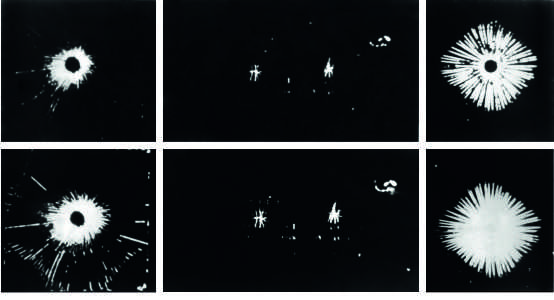

Ultrasound efficiency examples

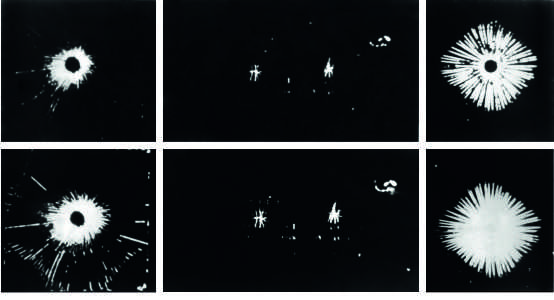

The upper row shows the results of defect visualization by conventional methods, and the lower row- with ultrasound applied.

We offer:

–the technology and equipment

– ultrasonic baths, ultrasonic generators, stationary and portable cavitometers;

– precise cleaning technology for complicated surfaces and holes;

– consultancy and technical support.

Technology description

The technology of ultrasonic purification is the method of preliminary cleaning of surfaces and hollows in open (discontinuous) monitored objects mostly with water or water solutions of chemical compounds in the ultrasonic field. The major intensifying factor of the ultrasonic purification is cavitation.

The cavitation bubbles collapsing, microjets of liquid emerge (their speed can reach several hundreds of meters per second) as well as shock waves. Exposed to the shock waves and high-speed microjets the impurity film (either solid or liquid) is destructed and is separated from the surface. In its turn cavitation ensures emulsification and dispersion of the separated impurity particles in the washing liquid. The ultrasonic purification makes it possible to remove the impurities from deep hollows or from capillary defects (liquid-penetrant flaw detector). The impurities from hollows in this case are pushed out by strong microjets of the washing liquid.

The efficiency of the ultrasonic purification is determined by the parameters of the ultrasonic field and properties of the washing liquid.

Advantages of using ultrasound

The use of ultrasound permits to considerably accelerate the purification procedure, to improve its quality, replace toxic liquids with harmless fireproof compositions.

General recommendations on ultrasound purification

– In the purification technology it is recommended to support the ultrasound intensity 3-5 times higher than the cavitation threshold.

– The distance from the emitting surface to the one under treatment, and the amplitude of the emitter vibrations should be selected on condition a well-developed zone of cavitation over the entire monitored surface. A cavitometer can help choosing an optimal mode of treatment.

– The exposure time in the sound field usually makes 3…10 min and should be increased as the gap between the part and the emitter grows.

– In order to control the operation mode of the ultrasound emitters it is recommended to use a cavitometer.

– – When selecting the washing liquid it is required to consider the influence of its properties, such as viscosity, density, gas content, saturated vapor pressure, and surface tension, on the cavitation activity and formation of the zone of cavitation

We offer:

– the technology and ultrasonic equipment to perform ultrasonic infiltration of capillary porous materials, namely: stationary and portable cavitometers, sonicator, ultrasonic bath.

– consultancy and technical support.

Technology description

The ultrasonic infiltration as a technological procedure is widely used in industry to impart special properties to products made from capillary porous materials, such as metal-ceramics, tissues, graphite, wood, etc. High efficiency of the ultrasonic infiltration can be accounted for deep and relatively fast penetration of infiltrating substances into pours and capillaries of the product. Intensification of the infiltration is realized mostly due to ultrasonic capillary effect, cavitation and vibrations of the capillary walls. Varying the properties of the infiltrating liquid (such as reducing viscosity, particle and molecule size in high-molecular compounds), as well as changing the interaction of liquid with the surface (decreasing the surface tension) is an important factor for accelerating the infiltration in the ultrasonic field..

The core of the method

The product under test is placed into the solution for infiltration. Then ultrasonic vibrations are excited in the liquid at the frequency of 20…50 kHz. The product is preserved in the infiltrating liquid exposed to ultrasound during the given time. The time of treatment is selected experimentally the operation mode of the emitters is controlled by the cavitometer.

Advantages of using ultrasound

The use of ultrasound results in intensification of technological processes (the infiltration time is reduced several times), enables to replace a double cycle of infiltration by a single cycle excluding the procedure of intermediate drying; improves the properties of ready-made products and materials.